Product Details

Granite Assembly

Granite Assembly

Granite Assembly

The Pinnacle of Integrated Structural Precision

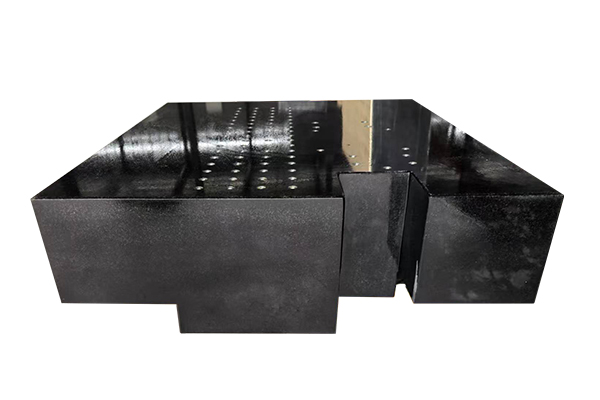

A Granite Assembly is a fully engineered system where the stable,monolithic properties of granite are leveraged to create an integrated structural chassis for high-precision machinery,instruments,or workstations.It represents a holistic design philosophy where the entire framework is conceived and executed as a singular,dimensionally invariant entity to achieve unparalleled system-level accuracy and long-term stability.

Design Philosophy:Unity and Invariance

The core principle is to minimize interfaces between dissimilar materials.By constructing the primary load-bearing structure from a single material(granite),the assembly ensures uniform thermal response,consistent vibration damping,and permanent geometric relationships.This eliminates errors arising from differential expansion,interface wear,and stress relaxation over time.

Signature Assembly Types

1.The Granite Metrology Frame

Description:A unified structure comprising a granite base,vertical columns,and horizontal bridge,forming the skeleton of ultra-precision CMMs,vision systems,or optical comparators.

Advantage:Creates a stable universe for measurement where the probe's relationship to the part is defined by a single,unchanging geometric frame.It eliminates alignment drift between separate components.

2.The Granite Multi-Axis Motion System

Description:An assembly where a granite base,guideways,and moving carriage are all precision-machined from granite,often for XY or XYZ stages in semiconductor inspection or photonics alignment.

Advantage:Provides nanometer-scale positioning repeatability because the moving element slides on a reference surface made of the same material,eliminating differential thermal effects and ensuring uniform friction characteristics.

3.The Granite Foundation Work Cell

Description:A large,monolithic granite block engineered as a multi-functional platform—integrating a super-flat work surface,precision T-slots or threaded inserts,and master-grade reference edges and angles.

Advantage:Serves as the absolute,unchanging datum for complex assembly,inspection,or machining processes,ensuring all operations share a common,perfect reference.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China