NewsDetails

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

author:admin time:2026-01-03 10:58:16 click:70

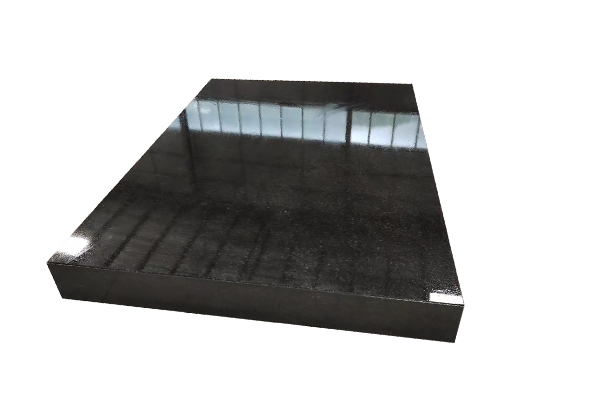

For the selection of high-precision measurement platforms,marble(natural granite)platforms are typically the superior and industry-standard choice.Below is a detailed comparative analysis:

1.Advantages of Marble(Granite)Platforms

Extremely High Stability:Natural granite has undergone hundreds of millions of years of natural aging,with minimal internal stress and almost no deformation.Its long-term stability far exceeds that of artificial materials.

Low Coefficient of Thermal Expansion:Minimal dimensional impact from temperature changes,making it suitable for high-precision measurements in temperature-controlled environments.

High Hardness and Wear Resistance:Mohs hardness of approximately 6-7,resistant to scratches,and offers a long service life.

Corrosion Resistance and Non-Rusting:Resistant to acids,alkalis,non-magnetic,and electrically insulating,suitable for complex environments.

Easily Machined to High Flatness:Can achieve micron or even sub-micron-level flatness through grinding.

Excellent Vibration Damping:Quickly absorbs vibrations,reducing measurement interference.

2.Granite(Commercial Term)vs.Marble

Clarification of Industry Terminology:

The term"marble platform"in the measurement industry typically refers to natural granite(primarily composed of quartz and feldspar),not soft marble(primarily composed of calcium carbonate).

True marble(e.g.,white marble)has low hardness and is prone to corrosion,making it unsuitable for measurement platforms.

The terms may be used interchangeably in commerce,so it is essential to confirm that the material is natural granite when purchasing.

3.Limitations of Granite Platforms

Relatively Brittle:Prone to chipping upon impact,requiring careful handling.

Heavy Weight:Requires professional handling and installation.

Higher Cost:High-quality granite platforms are more expensive than cast iron platforms but less costly than some precision ceramic platforms.

4.Comparison with Other Materials

Cast Iron Platforms:Prone to deformation and rust,require regular maintenance,commonly used in general industrial processing,and rarely used for high-precision measurement.

Ceramic Platforms:Performance is similar to granite,but costs are significantly higher,often used in ultra-precision fields(e.g.,optics).

Artificial Granite Platforms:Made from epoxy resin mixed with granite aggregates,offering better vibration damping but slightly inferior long-term stability compared to natural granite.

5.Application Scenario Recommendations

High-Precision Measurement(CMMs,Optical Platforms,Metrology Labs):Natural granite platforms are preferred.

Workshop On-Site Inspection:Cast iron platforms are acceptable(but require regular calibration).

Ultra-Precision Laboratories(e.g.,Laser Interferometry):Consider ceramic or artificial granite platforms.

Key Considerations for Purchase

Confirm Material:Request a material report from the supplier to ensure it is natural granite(e.g.,"Jinan Black,""Taishan Black").

Precision Grade:Select Grade 00,Grade 000,or higher based on requirements.

Inspection Report:Ensure third-party flatness and surface roughness test certificates are provided.

Installation Environment:Ensure the platform is placed on a temperature-stable,vibration-damped foundation(e.g.,an air-floating isolation base).

Conclusion

For high-precision measurement applications(e.g.,metrology labs,CMM bases),natural granite(often referred to as"marble platforms")is the industry-recognized optimal choice.Its stability,precision retention,and environmental adaptability outperform other common materials.When purchasing,ensure the material is confirmed as natural granite and validate it according to precision standards.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China