NewsDetails

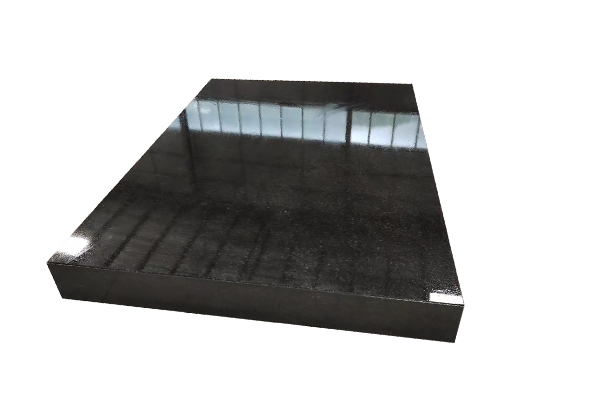

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

author:admin time:2026-01-04 11:01:28 click:154

Although accuracy degradation of marble(granite)platforms is inevitable after long-term use,it can be minimized through systematic maintenance and management,thereby preserving high precision over the long term.Below are specific key measures and practical recommendations:

I.Scientific Installation and Environmental Control

Stable Foundation Support

The platform must be installed on a solid,vibration-isolated foundation(such as a concrete base or air-floating isolation table)to prevent deformation caused by ground settlement or vibrations.

Use the three-point support principle or a professional multi-point leveling system to ensure even force distribution and prevent torsional stress.

Strict Constant Temperature Environment

The working environment temperature should be maintained at 20±1°C(precision grade)or 20±2°C(industrial grade),avoiding localized heat sources(sunlight,direct airflow from air conditioners).

Thermal equilibrium is required before use,especially when moving the platform from storage to the workshop.Generally,allow it to rest for 24-48 hours.

II.Standardized Usage and Daily Maintenance

Operational Protection

Handle workpieces gently;direct striking,dragging,or collision with the platform surface is strictly prohibited.

Clean workpieces before measurement to prevent hard particles such as iron chips or sand from scratching the platform.

Use dedicated pads or protective covers for heavy or sharp workpieces.

Cleaning and Care

For daily cleaning,use anhydrous ethanol or dedicated stone cleaner with a microfiber cloth.Avoid water or acidic solvents.

During long-term inactivity,apply stone anti-rust oil or dedicated protective wax and cover with a dust-proof cover.

Periodic Rotation of Usage Areas

Avoid prolonged pressure on specific areas by periodically adjusting the placement of workpieces to ensure even wear across the platform.

III.Systematic Accuracy Monitoring and Restoration

Regular Calibration

Frequency:For high-precision environments(e.g.,metrology labs),third-party calibration is recommended every 6-12 months;for general workshops,every 1-2 years is sufficient.

Method:Use electronic levels,laser interferometers,or autocollimators to measure flatness using a grid method and issue a report.

Restoration After Accuracy Degradation

Local Grinding:For minor scratches or dents,professional technicians can perform manual or CNC-based local repairs.

Complete Re-machining:When flatness exceeds tolerance,return the platform to the manufacturer or a professional organization for complete precision grinding to restore it to its original accuracy grade(note:the reduction in platform thickness must be controlled within safe limits).

IV.Establishment of Management Systems

Designated Responsibility

Appoint a dedicated equipment manager responsible for daily inspections,environmental records,and operational supervision.

Usage Records

Document each use,including time,workpiece type,placement location,and cleaning status,to facilitate traceability in case of anomalies.

Early Warning Mechanism

Initiate maintenance plans in advance when calibration data approach tolerance limits to prevent loss of accuracy control.

V.Common Misconceptions and Reminders

Misconception 1:Believing that marble is"wear-proof."

→Fact:While granite is wear-resistant,accumulated wear over time still affects accuracy.

Misconception 2:Using ordinary cloths or water for cleaning.

→Fact:Residual fibers and water stains can contaminate the surface and affect measurement results.

Reminder:Platform relocation must be performed by professionals using suction cups or air cushion equipment.Direct prying or dragging is strictly prohibited.

Conclusion

Maintaining the long-term accuracy of marble platforms is a systematic project that combines environmental control,standardized operations,regular calibration,and scientific management.By strictly implementing the above measures,the rate of accuracy degradation can be reduced by over 80%,significantly extending the platform's service life(typically,well-maintained high-quality platforms can last over 20 years).The core principle is:Prevention is better than restoration,and standardized operations outweigh costly repairs.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China