NewsDetails

What are the typical application scenarios for marble platforms in precision instrument assembly?

author:admin time:2026-01-06 11:04:39 click:98

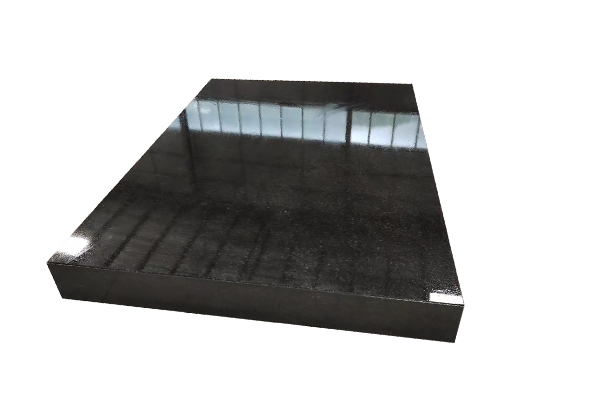

Marble(granite)platforms,thanks to their high stability,low thermal deformation,and excellent vibration damping,serve as critical foundational supports and reference planes in precision instrument assembly.The following outlines their typical application scenarios and core roles:

I.Core Application Scenarios

1.Reference Platforms for High-Precision Measuring Instruments

Coordinate Measuring Machine(CMM)Bases:

Serve as the rigid reference plane for CMMs,ensuring geometric accuracy during the movement of the probe in three-dimensional space while isolating ground vibrations and deformation.

Laser Interferometer/Optical Platforms:

Provide a stable,sub-micron-level flat surface for optical systems,minimizing environmental vibration interference with optical alignment.

Roundness/Contour Measuring Instrument Bases:

Support precision rotating shaft systems,ensuring accurate relative positioning between the measured workpiece and sensors.

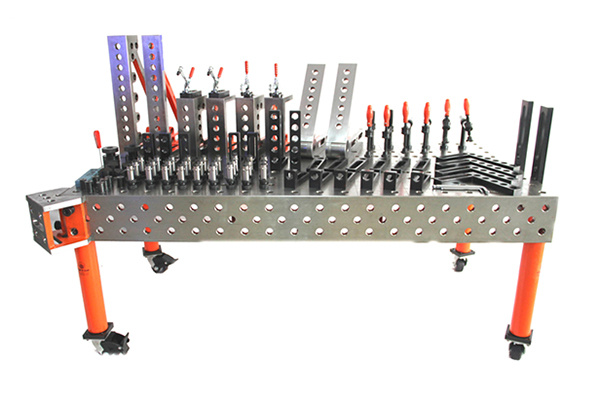

2.Precision Assembly and Adjustment Tooling

Semiconductor Equipment Assembly:

Used for leveling and aligning components in ultra-precision equipment such as lithography machines and wafer inspection systems,leveraging thermal stability to reduce thermal drift errors.

Aerospace Instrument Assembly:

Provide static adjustment platforms for highly sensitive devices like inertial navigation systems and star trackers,avoiding the impact of stress deformation from metal platforms.

Precision Mechanical Bearing Pre-Assembly Inspection:

Serve as reference planes for bearing clearance adjustment and gear meshing inspection,ensuring consistency in assembly gaps.

3.Support for Metrology and Calibration Systems

Calibration of Standard Gauges:

Used to verify the flatness and parallelism of gauge blocks and precision measuring tools,serving as high-grade reference planes in metrology labs.

Sensor Calibration Platforms:

Provide zero-deflection support for force and displacement sensors,ensuring calibration data is unaffected by base deformation.

4.Scientific Research Experimental Platforms

Micro-Nano Fabrication and Inspection Equipment:

Support sample stages for scanning electron microscopes(SEM)and atomic force microscopes(AFM),minimizing external vibration interference with microscopic imaging.

Gravitational Wave Detection/Quantum Experiment Bases:

Achieve ultra-low-frequency vibration isolation in extreme environments through multi-layer vibration isolation designs incorporating marble platforms.

II.Technical Reasons for Irreplaceability

Long-Term Retention of Geometric Accuracy:

Granite has near-zero internal stress after natural aging,and its flatness can remain unchanged for decades in temperature-controlled environments,far outperforming metal platforms(which are susceptible to mechanical stress and work hardening).

Excellent Dynamic Stability:

High density(approximately 2.8 g/cm³)and high damping coefficient enable rapid absorption of micro-vibrations generated by equipment motors and guides,preventing resonance transmission to precision components.

Thermal Inertia and Environmental Adaptability:

The coefficient of thermal expansion is only one-third that of steel,resulting in minimal thermal deformation in controlled environments(e.g.,20±0.5°C).It is also resistant to humidity and corrosion,making it suitable for cleanrooms and ultra-clean environments.

Flexible Functional Expansion:

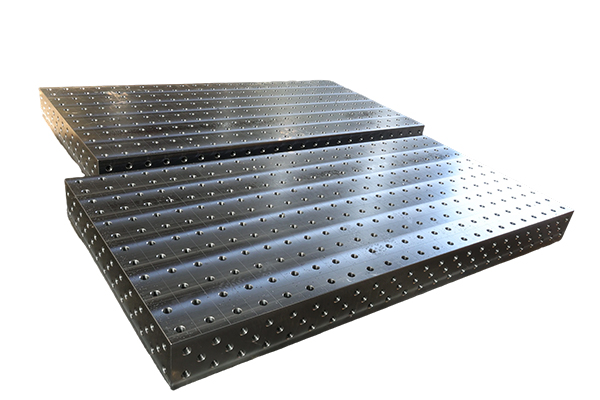

The surface can be machined with T-slots,threaded holes,or vacuum suction holes,accommodating modular tooling and fixtures to meet diverse,small-batch precision assembly needs.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China