Product Details

Non-standard granite component machining

Non-Standard Granite Component Machining

Bespoke Fabrication for Unique Precision Challenges

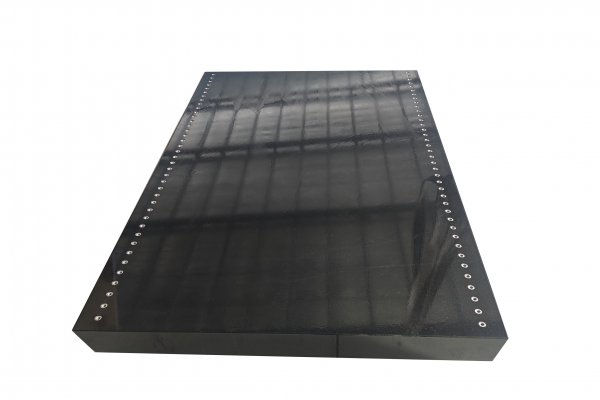

Non-Standard Granite Component Machining is the specialized process of designing and fabricating one-off or limited-run granite parts with geometries,features,or tolerances that fall outside standard catalog offerings.This service transforms custom design concepts into tangible,ultra-stable precision components for applications where off-the-shelf solutions are inadequate.

Scope of Customization&Complexity

We engineer and machine components that defy conventional form,including:

Complex Geometric Profiles:Parts with organic curves,multiple compound angles,non-parallel surfaces,or intricate internal contours not achievable with basic rectangular or cubic forms.

Integrated Functional Systems:Components that combine multiple features into a monolithic structure,such as a granite base with integrated guide rails,datum edges,coolant channels,and a network of precision mounting holes in a single piece.

Large-Scale or Unusual Dimensions:Extremely long,tall,or uniquely shaped components that require specialized handling and machining strategies beyond standard plate sizes.

Hybrid Material Components:Precision machining of granite to perfectly interface and bond with inserts of other materials(e.g.,metal,ceramic,composite)as part of the core design.

Micro-Precision Features:Machining of very small,high-tolerance details such as tiny grooves,miniature kinematic mounting points,or precise cavities for sensor integration.

The Custom Machining Workflow

Collaborative Design&Engineering Review:Our engineers work with your team to analyze the 3D model(CAD),optimize the design for granite's properties,and ensure manufacturability.We advise on optimal wall thickness,stress concentrations,and feature detailing.

Material Selection&Block Sourcing:Based on the component's function,we select the appropriate granite grade(e.g.,fine-grained black for stability,specific pink granite for low thermal expansion)and procure a raw block of suitable size and quality.

Advanced CNC Machining Strategy:Utilizing multi-axis CNC machining centers with diamond tooling,we execute a programmed sequence that may include 3D contour milling,deep pocketing,precision boring,and complex angular machining.

Precision Finishing&Lapping:Critical datum surfaces and functional faces undergo specialized grinding,honing,and lapping processes to achieve the specified flatness,parallelism,and surface finish—often to micron-level tolerances.

Secondary Operations&Integration:Installation of metal inserts,application of protective coatings,laser etching of markings,and final assembly with any non-granite sub-components.

Comprehensive Metrology&Certification:The finished component is fully inspected using CMMs,laser trackers,or interferometers to verify all critical dimensions and geometries against the original design intent.A full inspection report is provided.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China