Product Details

Metal Bellows Supplier

Provider of Precision Engineered Flexible Solutions

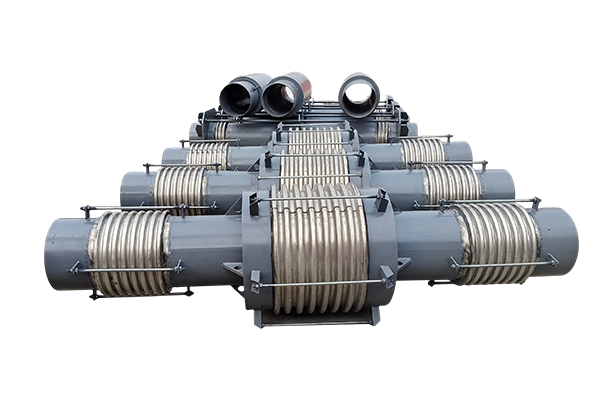

As a specialized supplier of metal bellows,we provide the essential flexible components that serve as the core of expansion joints,flexible connectors,and precision assemblies across high-performance industries.Our focus is on delivering engineered bellows solutions that meet exacting standards for movement,pressure,temperature,and cycle life.

Our Product Range&Core Capabilities

We supply custom-manufactured and standard metal bellows for diverse applications:

Expansion Joint Bellows:The primary flexible element for axial,lateral,angular,and universal expansion joints in piping and ducting systems.

Instrument&Sensor Bellows:Miniature,high-precision bellows for pressure sensing,volume compensation,and hermetic sealing in analytical instruments and control systems.

Flexible Coupling Bellows:Used in mechanical drives and torque transmission systems to accommodate misalignment while transmitting motion.

UHV(Ultra-High Vacuum)Bellows:Engineered for vacuum chambers and semiconductor equipment,providing flexibility with minimal outgassing.

Hydraulic&Actuation Bellows:Designed as seals or actuators in fluid power systems and precision mechanisms.

Material Expertise&Manufacturing

We source and form bellows from a range of high-performance materials to match application demands:

Stainless Steels:304,304L,316,316L,321,347 for general corrosion resistance and medium-high temperatures.

High-Temperature Alloys:Inconel®600/625,Incoloy®800/825,Hastelloy®for extreme heat and corrosive environments.

Exotic Alloys:Monel®,Titanium,and Nickel for specialized chemical or marine applications.

Manufacturing Processes:We supply bellows formed via Hydroforming(for seamless,lower-pressure units),Edge-Welding(for high-pressure,multi-ply,and complex geometries),and Deep Drawing techniques.

Technical Specifications&Custom Engineering

Our supply capability supports both standard and fully customized requirements:

Custom Geometries:Specific convolution profiles,diameters,lengths,and ply counts(single-ply through multi-ply).

Performance Parameters:Engineered to specified rates of movement(axial,lateral,angular),pressure ratings(internal and external),and operational temperature ranges.

End Configuration:Supplied as a bare bellows element or with integrated end fittings(flanges,weld necks,threaded connections)as required.

Accessories&Integration:Can provide associated components such as internal liners,external covers,hinge/lug kits,and tie rods for a complete assembly package.

Quality&Reliability Assurance

As a supplier,we understand the critical nature of metal bellows.Our products are backed by:

Rigorous Testing:Capabilities include pressure testing,leak testing(helium mass spec),and dimensional verification.

Material Certification:Full traceability of material mill certifications to applicable standards(ASTM,ASME,DIN).

Application Engineering Support:Technical collaboration to ensure the bellows specification aligns with your system's movement,life,and environmental requirements.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China