Product Details

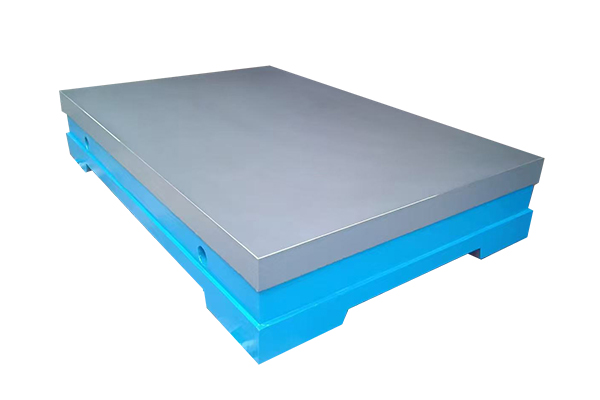

Cast Iron Surface Plate

The Robust Foundation for Precision Machining and Layout

The Cast Iron Surface Plate is a heavy-duty,engineered reference plane designed for stability and durability in demanding workshop and manufacturing environments.It serves as a reliable,rigid base for precise measurement,layout,inspection,and fixturing of components.

Inherent Strengths of Cast Iron Construction

High Rigidity and Dampening:Its dense structure offers exceptional vibration absorption and resistance to deflection under load,making it ideal for use with heavy components and active machinery.

Thermal Stability&Conductivity:Cast iron normalizes temperature variations quickly and evenly across its surface,reducing localized thermal distortion and promoting measurement consistency.

Superior Wear Resistance:The material is highly resilient to indentation and scratching under normal workshop use,maintaining surface integrity over time.

Stable,Stress-Relieved Foundation:Manufactured from high-grade,stress-relieved cast iron to ensure long-term dimensional stability and prevent warping.

Precision Machining&Finishing

Precision-Scraped Surface:The classic and most valued finish involves hand or machine scraping,which creates a uniform pattern of bearing points.This technique provides excellent oil retention,reduces stiction,and delivers a true,stable plane ideal for precise part movement and alignment.

Alternative Finishes:Also available with ground or milled finishes to meet specific application requirements and accuracy grades.

Reinforced Ribbing:Most plates feature a heavily ribbed underside for maximum strength-to-weight ratio,preventing flexing and ensuring consistent flatness.

Integrated Features:Often includes threaded mounting holes or T-slots along the sides or surface for securely anchoring vises,fixtures,and workpieces.

Core Applications

Precision Machining&Assembly:Provides an essential,stable work surface for layout,marking,and assembling components in toolrooms,machine shops,and production lines.

Heavy-Duty Inspection:Serves as a robust reference plane for checking the flatness and parallelism of large,heavy parts using height gauges,dial indicators,and surface straightedges.

Fixture&Tooling Base:Used as a foundational bed for constructing custom jigs,fixtures,and modular workholding systems due to its rigidity and mounting options.

Equipment Alignment&Installation:An indispensable tool for the precise leveling and alignment of machinery and industrial equipment on the shop floor.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China