Product Details

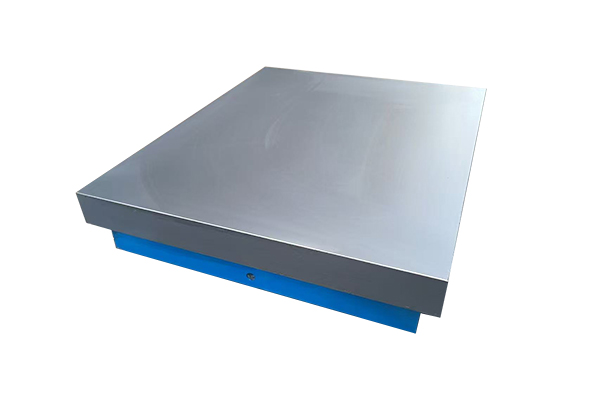

Cast Iron Surface Table

Cast Iron Surface Table

The Industrial-Grade Precision Foundation

The Cast Iron Surface Table is a large-scale,heavy-duty reference and work platform engineered for manufacturing,assembly,and precision inspection.It provides an exceptionally rigid,stable,and flat surface capable of supporting substantial weight while serving as a master datum for large components and complex tooling.

Engineered for Industrial Demands

Unmatched Structural Rigidity:Fabricated from high-grade,stress-relieved cast iron with a deeply ribbed,cross-braced underside.This design delivers maximum stiffness and minimizes deflection under heavy loads,ensuring geometric integrity during use.

Superior Vibration Damping:The dense microstructure of cast iron absorbs and dissipates energy far more effectively than granite or steel,creating a stable,"quiet"work surface that is ideal for sensitive measurements and precise assembly in active workshop environments.

Excellent Thermal Conductivity&Stability:Responds evenly to ambient temperature changes,reducing thermal gradients that can cause measurement drift.It quickly normalizes to shop temperature,promoting consistent accuracy.

Functional Versatility:Designed as both a precision reference plane and a robust work surface,capable of withstanding the rigors of direct machining,layout,welding fixturing,and assembly.

Precision Features&Specifications

Hand-Scraped Bearing Surface:The hallmark of a premium table.The surface is precision scraped to create a uniform pattern of bearing points.This provides optimal load distribution,reduces friction for moving components(like a Camelback straightedge),and allows for precise alignment through spotting techniques.

Integrated Modular Tooling:Typically features a grid of precisely machined and tapped mounting holes or T-slots on the surface and sides.This allows for the secure,repeatable attachment of vises,clamping systems,fixture plates,and custom workholding.

Heavy-Duty Construction:Built with thick walls,substantial legs or a robust base frame,and often includes lifting points for safe handling and installation.

Accuracy Grades:Available in workshop and inspection grades,with flatness tolerances suitable for a range of industrial applications,from fabrication to final quality assurance.

Primary Industrial Applications

Large Component Inspection:Provides the reference plane for checking the flatness,squareness,and profile of large machined parts,weldments,and assemblies using portable CMMs,height gauges,and optical tools.

Precision Assembly&Alignment:Serves as the foundational bed for building and aligning complex machinery,aerospace assemblies,automotive fixtures,and modular tooling systems.

Fixture&Jig Building:The standard base for constructing dedicated checking fixtures,welding jigs,and assembly platens due to its stability and integrated mounting capability.

Machining&Layout:Used as a direct work surface for layout,scribing,and supporting components during manual machining or fitting operations.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China