Product Details

Modular Welding Platform

Modular Welding Platform

The Scalable,Adaptive Foundation for Evolving Fabrication Needs

System Definition:A Platform That Grows With You

A Modular Welding Platform is a scalable and reconfigurable foundation system composed of standardized,interlocking units.Unlike monolithic tables,it is built from repeatable modules—like industrial LEGO®—that can be arranged,combined,and expanded to create a workspace of any size,shape,or function.This system provides the ultimate long-term flexibility,allowing your welding and fabrication capacity to evolve seamlessly alongside your business.

Core Architecture:The Building Blocks of Production

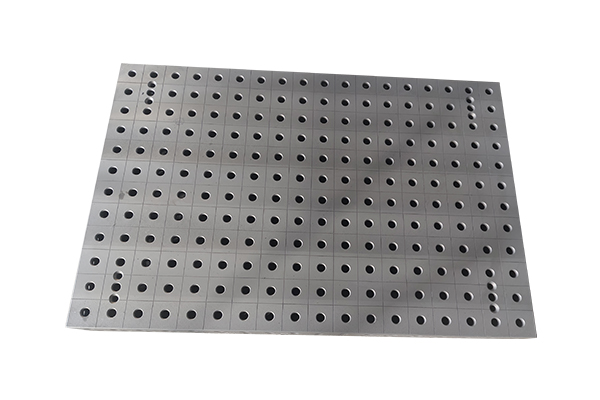

1.Modular Unit Design

Standard Module:The fundamental building block.Typically a 1m x 1m or 1.5m x 1.5m precision cast iron or steel square/rectangle with a standardized grid of mounting holes(e.g.,16mm holes on 100mm centers).

Interface System:Modules feature a patented kinematic coupling or precision-machined tongue-and-groove system on all four sides.This ensures that when bolted together,multiple modules form a single,continuous,and accurate surface with consistent flatness across seams.

Integrated Leveling:Each module has four independent,heavy-duty leveling feet with large adjustment range,allowing the entire platform to be leveled on uneven floors.

2.System Configurability

Expandable Surface Area:Start with a 2m x 1m bench.Expand to a 4m x 3m floor platform,or an L-shaped cell,or multiple independent stations—all using the same core modules.

Functional Variety:

Standard Grid Modules:For general fixturing.

T-Slot Modules:For specialized clamping or framing.

Solid Top Modules:For layout or heavy grinding.

Water-Cooled Modules:For high-heat applications.

Low-Profile"Fill"Modules:To create continuous floors or specific shapes.

Height&Ergonomic Options:Modules can be mounted on different height leg systems(bench height,stand-up height,sit-down height)and mixed within the same layout.

3.Integrated Utility Matrix

The true power lies in the integrated infrastructure that turns modules into a smart platform:

Utility Chase Channels:Modules have internal raceways that align when connected,creating continuous channels for:

Air Lines(for pneumatic tooling)

Electrical Busways(110V/220V/480V with drop-down outlets)

Data&Communication Cables(Ethernet,IO-Link)

Coolant/Vacuum Lines

Centralized Connection Hub:A master distribution panel connects to shop services,distributing utilities to each module via the internal raceways.

Key System Advantages

Infinite Scalability:Truly future-proof.Add capacity linearly(more length)or areally(more width)as production demands increase.No need to sell an old table and buy a bigger one.

Layout Agility:Reconfigure the shop floor layout in a weekend.Convert a large assembly platform into multiple smaller work cells,or create a flow line by arranging modules in sequence.

Redundancy&Maintenance:If a single module is damaged,you replace only that module(1m x 1m),not an entire 3m x 2m table.Downtime and cost are minimized.

Optimized Investment:Purchase only what you need today.Fund expansion modules from future project budgets,spreading capital expenditure over time.

Specialized Zones:Create dedicated areas within one continuous platform(e.g.,a water-cooled welding zone next to a clean assembly zone next to a magnetic clamping zone).

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China