Product Details

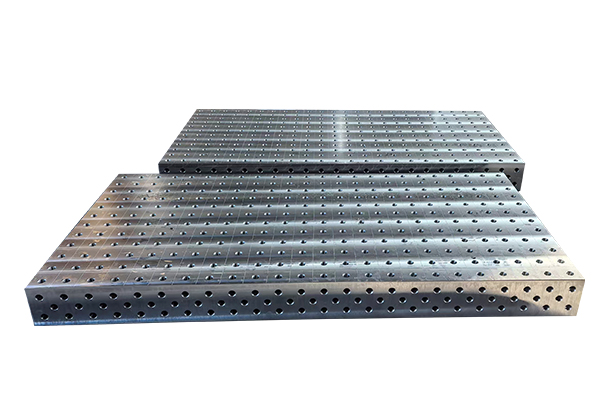

Modular Fixture System

Modular Fixture System:The Ultimate Tooling Ecosystem for Precision Workholding

Reconfigurable.Repeatable.Revolutionary.

Our Modular Fixture System transforms any welding table,machining plate,or assembly platform into a highly efficient,zero-point clamping work cell.This integrated ecosystem of precision tooling enables you to set up,secure,and reproduce complex workpiece positions in seconds—not hours—dramatically increasing throughput while guaranteeing uncompromising accuracy.

System Core Philosophy:The 5-Sided Fixturing Principle

Go beyond simple clamping.Our system allows secure,simultaneous fixturing from five sides(X,Y,Z,and two rotational planes),completely immobilizing even the most challenging geometries directly from the precision hole grid of your table.

Core System Components

1.Foundation&Interface

Precision Plates&Tables:The system starts with a grid-plate(cast iron or steel)featuring accurately spaced and sized mounting holes(16mm,28mm,or¾").

Zero-Point Clamping Modules:The heart of rapid changeover.These modules allow entire fixture assemblies to be removed and repositioned with micron-level repeatability,locking into the table grid with a single lever.

2.Structural Framing&Supports

Box Beam Grid Kits:Create a rigid,adjustable 3D framework above your table for overhead tool mounting or part suspension.

Angle Brackets&Cube Blocks:High-precision 90°and multi-angle building blocks for constructing square,stable fixture bases.

Adjustable Support Columns&Jacks:Provide fully variable height support for uneven parts or to prevent welding distortion.

3.Clamping&Hold-Down Elements

Multi-Axis Clamps:Compact,low-profile clamps that exert force in multiple directions from a single mounting point.

Toggle Clamps&Swing Clamps:For rapid manual clamping and unclamping of parts.

Edge Clamps&Push-Pull Clamps:Apply perpendicular or lateral pressure to secure parts against locators.

Magnetic Clamps(Ferrous):For instant,temporary holding during initial tacking.

4.Locating&Positioning Elements

Diamond Pins&Round Locating Pins:For exact,repeatable part positioning(2-pin system).

Rest Buttons&Support Pins:Hardened contact points to establish a precise datum plane.

V-Blocks&Angle Plates:For holding round or cylindrical stock and creating reference faces.

Linear Stop Blocks&Edge Guides:Adjustable stops for quick,consistent part placement.

5.Specialized Accessories

Quick-Change Spindle Mounts:For mounting drills,taps,or deburring tools directly into the fixture.

Laser Projection Modules:Project weld paths or part outlines directly onto the workpiece.

Modular Vise Jaws:Customize standard vises with hole-grid compatible jaws for part-specific holding.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China