Product Details

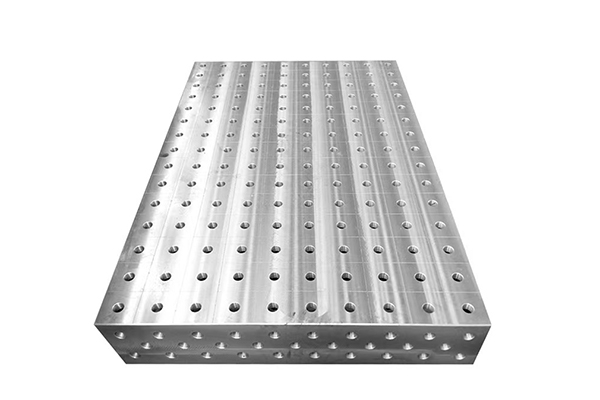

Precision Welding Platform

Precision Welding Platform:The Integrated Foundation for Advanced Fabrication

Where Ultra-Precision Meets Complete Process Integration

A Precision Welding Platform is more than a table—it is a fully integrated,system-level foundation designed for the most demanding applications in advanced manufacturing,aerospace,robotics,and mission-critical fabrication.It combines the unparalleled flatness and accuracy of a precision table with built-in process support,digital integration,and environmental control to create a controlled,optimized"workspace ecosystem."

Core Concept:A Unified Process Cell

Unlike a standard precision table,a Platform is engineered as a complete work cell core,anticipating and facilitating every step of the fabrication process—from part placement and fixturing to welding,in-process measurement,and final verification—all within a single,controlled reference frame.

System Architecture&Key Components

1.The Ultra-Precision Foundation

Monolithic Reference Surface:A massive,thermally stable granite,polymer concrete,or high-grade cast iron base.Provides inherent vibration damping and long-term geometric stability measured in microns.

Modular Top Plate System:A standardized grid plate(e.g.,16mm/100mm)is mounted onto the monolithic base.This plate can be replaced,reconfigured,or swapped for different projects without compromising the base's calibration.

Integrated Leveling&Anchoring:Self-leveling air isolators or precision mechanical feet with built-in shock absorption,permanently anchored to the floor.

2.Integrated Process Support Systems

Embedded Utility Grid:Channels within the platform carry:

Clean,Dry Air:For pneumatic tooling and clamping.

Coolant&Chilling Lines:For thermal management of the workpiece or table.

Electrical Power&Data:Busways for 110V/220V/480V and Ethernet/Cat6,with outlets at the table edge.

Centralized Vacuum&Extraction:Ports for fume extraction or vacuum clamping.

Environmental Management:

Thermal Enclosures:Optional clear or solid panels to create a temperature-stable zone.

Localized Downdraft:Built-in,perimeter-based fume extraction.

3.Digital Integration&Smart Features

Integrated Metrology:Platform can be ordered with a calibrated,NIST-traceable laser tracker nest or CMM mounting points,allowing in-situ inspection without moving the part.

Grid Digitization:Each mounting hole has a unique digital ID(QR code or RFID).When scanned with a tablet,it brings up the digital twin of the fixture setup in CAD software.

IoT-Ready:Sensors monitor table flatness,temperature,and vibration,feeding data to a dashboard for predictive maintenance and process control.

4.Advanced Accessory Integration

Gantry&Robot Mounting Rails:Precision-ground rails mounted on the platform's sides for integrating CNC milling heads,laser welders,or robotic arms with a common,accurate datum.

Automated Tool Changers:Racks for storing and automatically changing between modular fixture kits or welding torches.

Dynamic Tooling Plates:Electrically or pneumatically actuated sub-plates that can tilt,rotate,or translate the workpiece under program control.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China