Product Details

3d Flexible Welding Table with Welding Jigs

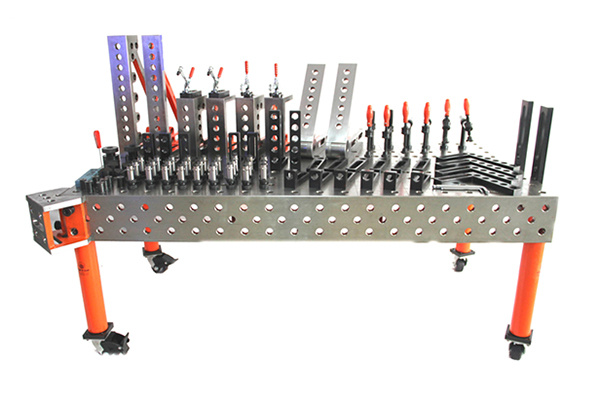

3D Flexible Welding Table with Welding Jigs

The Ultimate Modular Fixturing Solution for Complex Assembly

Overview:A Complete 3D Workholding Ecosystem

The 3D Flexible Welding Table is not just a table—it's a reconfigurable 3D space frame system that enables precise positioning and clamping of complex workpieces from any angle.When combined with a comprehensive suite of specialized welding jigs,it creates a complete digital-physical fixturing system that dramatically reduces setup time while ensuring repeatable accuracy.

System Architecture

1.Core Platform:3D Modular Space Frame

Base Structure:Heavy-duty aluminum or steel T-slot extrusions forming a rigid cubic frame

Multi-Plane Mounting:Precision mounting holes or T-slots on all six faces(top,bottom,four sides)

Scalable Design:Modular sections can be added or reconfigured to create any size workspace

Integrated Leveling:Adjustable feet with precision bubble levels or digital inclinometers

2.Precision Positioning Grid

3D Coordinate System:Every mounting point has defined X,Y,Z coordinates

Standardized Grid Pattern:50mm or 100mm spacing in all three dimensions

Multi-Angle Mounting:45°and 30°adapter plates for compound angle setups

Digital Reference System:Optional laser-etched coordinate markings with QR code indexing

Welding Jig System Components

1.Universal Positioning Elements

3D Adjustable Arms:Articulating arms with locking ball joints(360°rotation+180°tilt)

Magnetic Base Pivots:High-strength magnetic bases with precision swivel heads

Linear Slides:Precision ground rails with micrometer adjustments in X,Y,Z axes

Rotary Positioners:Manual or motorized 4th-axis rotation units with digital angle readouts

2.Specialized Welding Jigs

Pipe&Tube Jigs:Self-centering V-blocks with adjustable angles for pipe intersections

Plate Alignment Jigs:Wedge-style aligners with built-in gap measurement

Corner Clamping Jigs:Internal/external 90°fixtures with adjustable pressure points

Circular Weld Jigs:Rotating ring fixtures for circumferential welds

Profile Jigs:Customizable contour followers for irregular shapes

3.Smart Clamping Technology

Heat-Resistant Clamps:Ceramic-coated or copper-plated clamps that resist weld spatter

Quick-Change Fixtures:Lever-actuated clamps with<2 second changeover

Remote Control Clamping:Pneumatic/electric clamps controlled from welding position

Force-Limiting Clamps:Preset torque clamps to prevent workpiece distortion

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China