Product Details

Customized Flexible Welding Solution

Customized Flexible Welding Solution

Customized Flexible Welding Solution

Your Process,Perfected–A Tailored Ecosystem for Unmatched Agility

Beyond the Catalog:A Solution Engineered Around You

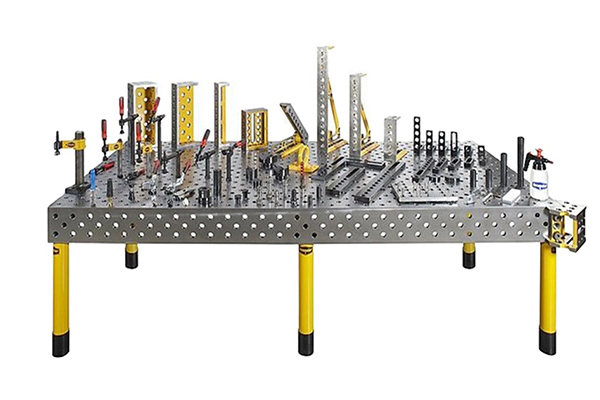

A Customized Flexible Welding Solution is not a product you buy—it is a manufacturing capability we co-create.We move beyond standard tables and modular kits to engineer a fully integrated workholding and fabrication ecosystem specifically for your parts,your processes,and your production goals.This is the ultimate expression of flexible manufacturing:a turnkey cell that combines precision fixturing,ergonomic workflow,and digital control into a seamless extension of your team’s expertise.

Our Co-Creation Methodology:The 5-Phase Partnership

Phase 1:Deep-Dive Discovery&Process Mapping

Part Family Analysis:We analyze your components for geometric commonalities,weld types,and volumes.

Current State Value Stream Mapping:We identify bottlenecks,non-value-added time,and quality pain points in your current process.

Future State Visioning:We define target KPIs:setup time reduction,first-pass yield increase,footprint optimization.

Phase 2:Concept&Digital Twin Development

Virtual Cell Design:Using your 3D CAD models,we build a digital twin of the proposed solution,simulating the entire workflow from part load to unload.

Fixturing Strategy:We design a hybrid solution combining:

Modular Elements:For flexibility across part families.

Dedicated Sub-Fixtures:For high-speed handling of repetitive features.

Automated Elements:Where justified for cycle time reduction.

Ergonomic&Safety Simulation:We validate operator reach,visibility,and safety before any metal is cut.

Phase 3:System Architecture&Integration

Your solution is built as a cohesive system from these integrated layers:

Layer 1:The Intelligent Foundation

Custom-Sized Platform:A precision granite,polymer concrete,or stabilized steel base,sized perfectly for your part envelope and workflow.

Hybrid Grid Pattern:A combination of hole sizes and patterns(e.g.,16mm for fine tooling,28mm for heavy clamping)optimized for your tooling.

Integrated Auxiliaries:Built-in fume extraction plenums,utility drops for air/power/water,and cable management raceways.

Layer 2:The Adaptive Fixturing Heart

Family-Specific Tooling Kits:A curated set of modular components pre-configured for rapid changeover between your specific part families.

Quick-Change Pallet System:For high-mix scenarios.Operators fixture parts offline on pallets,which then locate and clamp onto the main platform in seconds with micron repeatability.

Active Alignment&Sensing:Integrated probes,vision systems,or laser projectors that verify part position before welding and compensate for minor variations.

Layer 3:The Process Enhancement Layer

Positioning&Manipulation:Integrated 2-axis slides,manual turntables,or fully automated 6-axis servo positioners to present the weld joint in the optimal position.

Thermal Management:Custom copper backup bars,chill plates,or induction pre-heat systems engineered for your specific welds to manage distortion.

Accessory Integration:Dedicated holders for your specific welding torches,wire feeders,and inspection tools.

Layer 4:The Digital Control Layer

Unified Human-Machine Interface(HMI):A single touchscreen that controls fixture clamping,positioner movement,and can interface with your welding power source.

Setup Recipe Management:The operator selects the part number;the system calls up the digital fixture layout,positioner program,and suggested weld parameters.

Data Connectivity:OPC-UA or MTConnect interface to feed setup time,cycle time,and first-part validation data directly into your MES or ERP system.

Phase 4:Build,Validation&Acceptance

Factory Acceptance Test(FAT):You witness the complete solution running with your parts(or representative prototypes)at our facility.

Process Capability Study(Cpk):We demonstrate the system’s ability to hold your critical tolerances consistently.

Documentation&Training:Delivery includes full digital manuals,setup libraries,and hands-on training for your operators and maintenance team.

Phase 5:Launch&Continuous Support

On-Site Installation&Integration:Supervised by our engineers.

Performance Benchmarking:We measure achieved KPIs against project goals.

Evolution Partnership:As your products evolve,your system can be expanded or reconfigured with additional modules.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China