Product Details

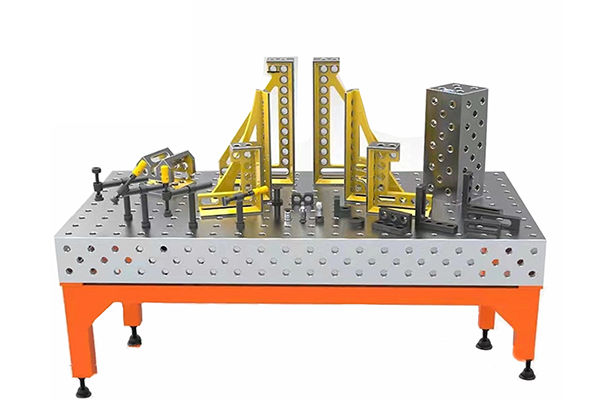

Flexible Modular Fixturing System

Flexible Modular Fixturing System

The Ultimate Reconfigurable Workholding Platform for Modern Manufacturing

System Overview:The Tooling Revolution

A Flexible Modular Fixturing System(FMFS)is a complete engineered kit of precision components that enables manufacturers to construct,modify,and replicate custom workholding fixtures on-demand—without dedicated machining.By replacing single-purpose jigs with an intelligent library of standardized elements,FMFS delivers unprecedented agility,accuracy,and cost efficiency for welding,machining,assembly,and inspection.

Core Philosophy:Build Fixtures,Not Parts

Traditional manufacturing requires designing and machining a custom fixture for every new part—a process that consumes weeks of time and thousands of dollars.

An FMFS transforms this paradigm:

✅Design in hours,not weeks using digital libraries

✅Assemble in minutes,not days with standardized hardware

✅Reuse infinitely across product families

✅Modify instantly for engineering changes

System Architecture:The Building Blocks of Precision

1.Foundation Grid Systems

Base Plates&Tables:Stress-relieved cast iron or steel plates with precision-machined grid patterns(16mm/28mm holes,50mm/100mm spacing).The datum for all fixtures.

Sub-Plates&Angle Plates:Create elevated or angled mounting surfaces while maintaining squareness and flatness.

T-Slot Framing:Extruded aluminum/steel profiles for building 3D frameworks and lightweight structural supports.

2.Structural Elements

Box Beams&Struts:Rigid,hollow sections with mounting holes on all faces for constructing stable 3D frames.

Cube Blocks&Multi-Sided Brackets:Precision-machined blocks(100mm³typical)with tapped holes on multiple faces for connecting elements in any orientation.

Adjustable Support Columns:Threaded posts with fine-pitch adjustment for establishing precise Z-height datums.

3.Locating&Positioning Elements

Kinematic Locators:Hardened diamond pins,round pins,and cone locators for repeatable part positioning(2-4-1 locating principle).

Rest Buttons&Support Pins:Carbide-tipped contact points to establish stable datum planes.

Edge Stops&Adjustable Guides:For quick part alignment along reference edges.

4.Clamping&Hold-Down Elements

Multi-Axis Clamps:Compact units that apply clamping force in X,Y,and Z directions simultaneously.

Quick-Change Clamps:Lever-actuated or pneumatic clamps for rapid loading/unloading.

Specialized Clamps:Profile clamps,strap clamps,and vacuum pods for unique applications.

5.Specialized Modules

Rotary Positioners:Manual or servo-driven 4th/5th axis units integrated into the modular system.

Measuring&Inspection Modules:Built-in probe mounts,height gauges,and surface plates.

Heat Management:Copper chill bars,heat sinks,and cooling channels for weld distortion control.

Digital Integration Ecosystem

Virtual Design&Simulation

CAD Plugins:Direct integration with SolidWorks,Siemens NX,CATIA,and Fusion 360

Component Libraries:Digital twins of every physical component for virtual fixture design

Collision Detection:Automatic interference checking before physical assembly

Setup Documentation:Auto-generated assembly instructions,BOMs,and torque specifications

Smart Manufacturing Features

QR Code/RFID Tracking:Every component has a unique ID for inventory management and setup recall

AR Assembly Guides:Step-by-step visual instructions via tablet or smart glasses

Digital Twin Synchronization:Real-time connection between physical fixture and CAD model

Process Monitoring:Integration with MES/ERP systems for production tracking

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China