Product Details

3D Flexible Welding Platform

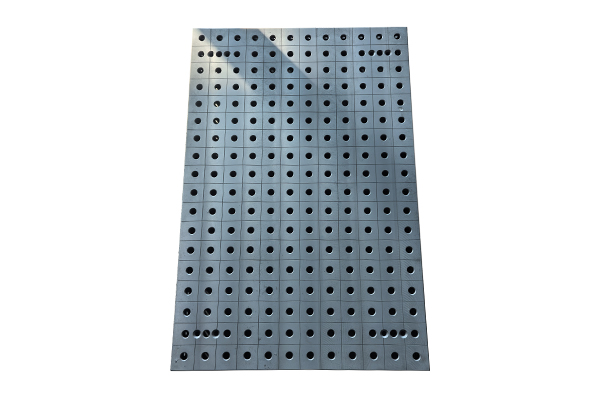

3D Cast Iron Welding Table

The Ultimate Vibration-Damped Foundation for Precision Fabrication

Overview:The Industry Standard Reborn in 3D

The 3D Cast Iron Welding Table represents the pinnacle of traditional material science meeting modern modular fixturing needs.Engineered from high-grade,stress-relieved cast iron with precision-machined mounting surfaces on multiple sides,it provides an unrivaled combination of massive vibration damping,exceptional thermal stability,and true 3D workholding capability.This is not merely a tabletop—it’s a volumetric fixturing cube designed for the most demanding precision welding,assembly,and inspection tasks.

Core Material Advantage:Why Cast Iron?

Superior Damping Capacity

Vibration Absorption:Cast iron's graphite microstructure provides 6-10 times better vibration damping than steel of equivalent mass.This is critical for:

Achieving clean,spatter-free TIG and laser welds

Maintaining accuracy during in-situ machining operations

Ensuring stable readings during on-table inspection/CMM work

Sound Deadening:Creates a noticeably quieter,more focused work environment.

Exceptional Thermal Stability

Low Thermal Expansion:Coefficient of~11µm/m·°C(similar to steel)but with superior thermal mass and isotropic behavior.

Heat Sink Effect:The massive cast mass absorbs and dissipates welding heat evenly,minimizing localized thermal distortion of the table surface.

Stress-Relieved Structure:All castings undergo prolonged thermal stress-relief cycles,ensuring long-term dimensional stability against internal stresses.

Wear Resistance&Longevity

Hardened Surfaces:The mounting faces and holes can be flame-hardened or induction-hardened to 45-55 HRC,resisting wear from repeated tooling insertions.

Corrosion Resistance:The natural graphite content provides some inherent corrosion resistance,often enhanced by protective coatings.

3D Fixturing Architecture:Beyond a Flat Surface

1.Multi-Side Precision Machining

A true 3D table features at least two(typically three)mutually perpendicular precision faces—not just a top surface.

Primary(Top)Surface:The main work area with a standard grid of mounting holes(e.g.,16mm on 100mm centers).

Vertical(Side)Surfaces:One or two vertical faces,machined square to the top within±0.02 mm,with the same or similar hole grid.Enables:

Side-mounting of parts for horizontal welds

Building 90°fixtures directly from the table

Mounting tooling plates or angle plates for complex setups

Optional End Surfaces:Some models include a fourth machined face.

2.Structural Design for 3D Rigidity

Monolithic"L"or"Box"Casting:The table is cast as a single,rigid L-shaped or box-shaped structure,not assembled from separate plates.This guarantees permanent squareness and rigidity.

Heavy Ribbing:The internal structure features a dense network of reinforcing ribs,optimized through finite element analysis(FEA)to resist torsion and bending under load from any direction.

Kinematic Mounting Points:Designed with three primary mounting/leveling points to avoid distortion from the shop floor.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China