Product Details

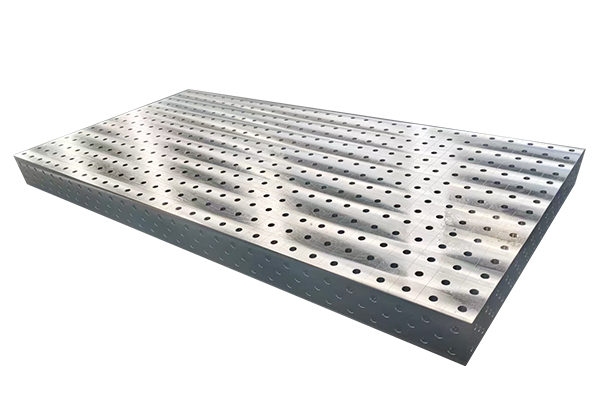

3D Cast iron welding table

3D Cast Iron Welding Table

The Unmatched Foundation for Precision,Stability&Versatility

System Definition:A Volumetric Precision Instrument

A 3D Cast Iron Welding Table is a monolithic,multi-faced precision foundation engineered from high-grade cast iron.Unlike standard single-surface tables,it provides machined and calibrated work surfaces on multiple planes(typically top and one or two sides),creating a true 3D volumetric datum for fixturing,welding,assembly,and inspection.It is the definitive choice where vibration damping,thermal stability,and built-in geometric references are non-negotiable.

The Cast Iron Advantage:Material Science at Work

1.Superior Vibration Damping(6-10x Better Than Steel)

Microstructural Magic:The graphite flakes within cast iron’s matrix absorb vibrational energy,converting it to minute heat.

Critical Impact:Eliminates“chatter”during TIG,laser,or micro-welding.Ensures stable readings for on-table CMM or laser tracker use.

2.Exceptional Thermal Stability&Mass

Thermal Inertia:High mass and specific heat capacity act as a massive heat sink,absorbing welding heat without localized distortion.

Isotropic Behavior:Expands and contracts uniformly,preserving geometry under shop temperature fluctuations.

Stress-Relieved:All castings undergo prolonged thermal aging to relieve internal stresses,guaranteeing long-term dimensional stability.

3.Wear Resistance&Long Service Life

Natural Lubricity:Graphite provides self-lubricating properties,reducing galling and wear on tooling.

Surface Hardening:Critical work surfaces and holes can be flame or induction hardened to 45-55 HRC.

Corrosion Resistance:Superior to most steels;often enhanced with protective coatings.

3D Architecture:Beyond a Flat Plate

Core Design Principle:Monolithic"L"or"U"Casting

The table is cast as a single,integral unit—not bolted assemblies—ensuring permanent geometric integrity between surfaces.

Standard Configurations:

Two-Sided(L-Type):One horizontal top surface+one vertical side surface,precision machined square to each other.

Three-Sided(U-Type):Top surface+two perpendicular side surfaces,forming an internal corner.

Four-Sided(Box-Type):Top,two sides,and one end—fully enclosing a work volume.

Precision Machining Specifications:

Surface Flatness:As fine as 0.02mm/m for metrology-grade tables.

Squareness(Side to Top):Typically≤0.03mm/300mm.

Hole Grid:Precision-reamed mounting holes(16mm or 28mm)on standardized centers(50mm/100mm)on all machined faces.

Recommended News

Recommended News

-

What are the typical application scenarios for marble platforms in precision instrument assembly?

2026-01-06 11:04:39

-

What are the key parameters to consider when selecting a marble platform?

2026-01-05 11:03:18

-

How to Prevent Accuracy Degradation of Marble Platforms After Long-Term Use?

2026-01-04 11:01:28

-

Marble Platform vs. Granite Platform: Which Material is More Suitable for High-Precision Measurement?

2026-01-03 10:58:16

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China