NewsDetails

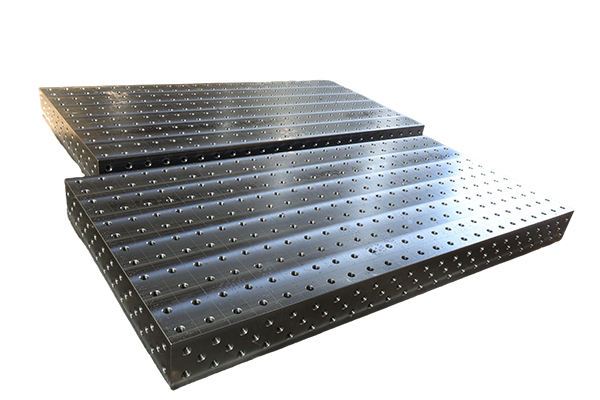

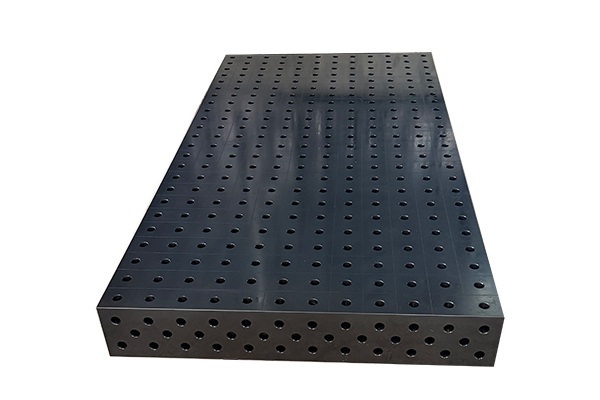

How to check if the flatness of the newly installed cast iron surface plate is qualified?

author:admin time:2026-01-17 14:55:13 click:158

To inspect whether the flatness of the newly installed cast iron surface plate is qualified, standard procedures must be followed. First, confirm the environment and installation to ensure that the platform is in a constant temperature and vibration-free environment, and has been properly leveled and stabilized according to the designed support points. Then, thoroughly clean the surface and prepare core tools such as a precision level, straightedge, and feeler gauge.

The most commonly used and efficient method is the electronic level bridge plate method. The surface of the platform is divided into grids, and a level gauge is used in conjunction with a bridge plate to take readings along each measurement line in sections. The data is then processed through calculation or software to obtain an accurate flatness error value. For general requirements, a precision knife edge straightedge can also be used in conjunction with a feeler gauge for rapid inspection. The flatness is estimated by observing the light gap or measuring the gap. Finally, the measured flatness error value is compared with the national standard or contract technical agreement for the factory accuracy grade (such as Grade 00, Grade 0, Grade 1) of the fixed plate. If the measured error is less than or equal to the standard tolerance, it is considered to be qualified. It is important to keep complete inspection records as a benchmark for acceptance and maintenance. For high-precision requirements, it is recommended to entrust a professional metrology institution to conduct authoritative inspection using a laser interferometer.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China