NewsDetails

How to choose the appropriate specifications (size and load capacity) of cast iron surface plates according to work requirements?

author:admin time:2026-01-17 14:41:29 click:137

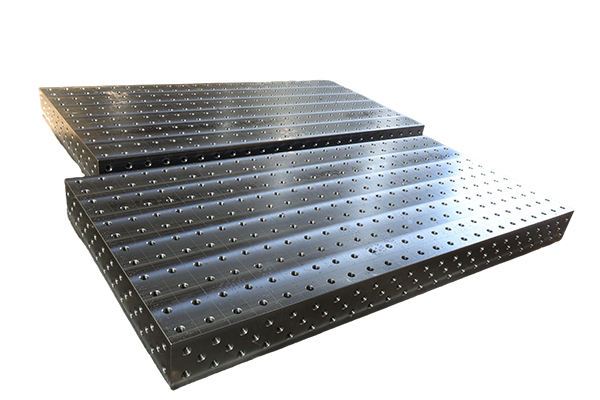

When selecting the specifications of a cast iron surface plate(also known as a cast iron platform or scribing platform),the core principle is to"match the work requirements and reserve a safety margin".Here are clear and executable selection steps and considerations:First,determine the core specifications:size(length×width).The choice of size depends on the size of the largest workpiece and the working method.

Basic principle:For individual workpieces,the size of the fixture plate should be at least larger than the maximum contour size of the workpiece.For example,if the maximum length of the workpiece is 1.5 meters,it is recommended to choose a fixture plate of 2 meters by 1 meter or 2 meters by 1.5 meters to ensure sufficient space around the workpiece for placing tools,measuring tools,and performing operations.

Multiple/Combined Work:If multiple workpieces need to be placed simultaneously or components need to be assembled,the dimensions should be determined based on the total layout area.

Future expansion:Consider the largest workpiece that may be processed in the future and appropriately reserve space.

Empirical formula:Minimum operating margin:from the edge of the workpiece to the edge of the fixed plate,generally reserved 300-500mm.

Suggested dimensions:Fixed table length≈maximum length of workpiece+(500~1000mm)Fixed table width≈maximum width of workpiece+(500~800mm)II.Determine key performance:Bearing capacity The bearing capacity depends on the structure of the fixed table itself and the maximum working load.

Understand two concepts:Self-weight:The weight of the fixed platter itself,which forms the foundation of its rigidity and stability.

Maximum allowable load:The uniformly distributed load that the table can withstand while maintaining accuracy and safety(unit:ton/square meter or kilogram/square meter).This is a key parameter provided by the manufacturer.

Calculation and selection steps:Estimating the maximum working load:Calculate the"maximum total weight"that may be imposed on the fixed platen by the workpiece,fixture,tool,and even the operator.

Calculate load intensity:Divide the total weight by the contact area between the workpiece and the fixed platen(if the contact area is small,consider the most unfavorable scenario),to obtain the actual load intensity(unit:ton/square meter).

Comparison and safety margin:It must be ensured that the actual load strength is less than the rated maximum allowable load of the fixed plate.

Suggested safety factor:For dynamic loads(with impact and movement)or long-term heavy loads,choose a fixed plate with a rated load that is more than 1.5 times the actual calculated load.

Consider load distribution:Avoid bearing extreme loads in localized areas for extended periods.Efforts should be made to distribute the load evenly.For heavy concentrated loads,special considerations are required,and manufacturers may enhance the design of internal rib plates.

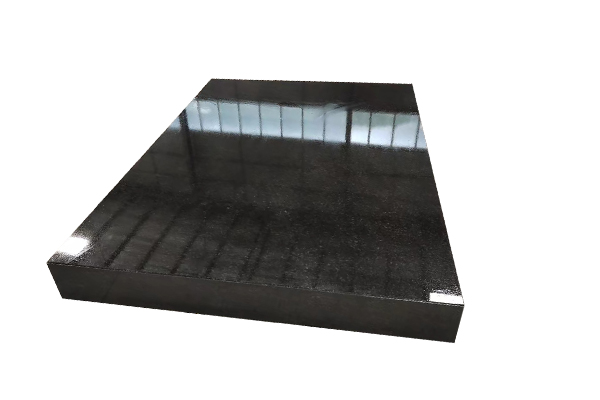

Third,the choice of accuracy level is closely related to precision.The larger the size and the heavier the load,the more difficult it is to maintain high accuracy,and the higher the cost.

Precision inspection and scribing:Choose a high-precision surface plate of Grade 00,Grade 0,or Grade 1,but be aware that its load-bearing capacity is usually lower than that of lower-precision surface plates of the same grade.

For general welding,assembly,and fitter work,choosing Level 1,Level 2,or Level 3 is sufficient,as they offer stronger load-bearing capacity and better cost-effectiveness.

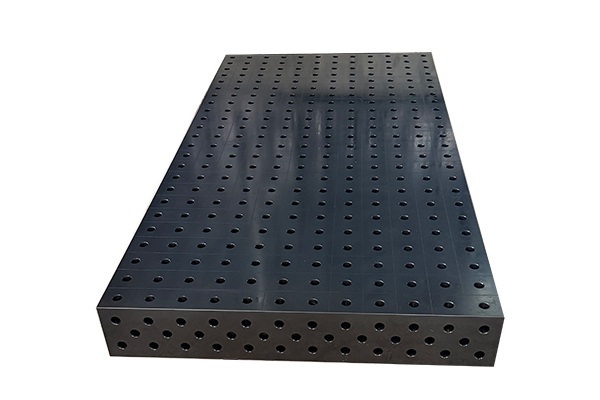

IV.Other important considerations Structural design:Ribbed plate structure:honeycomb,cross-shaped,or cross-shaped reinforcement ribs.The denser and taller the ribbed plate,the better its rigidity and load-bearing capacity.Cross-shaped reinforcement ribs are preferred for heavy-duty work.

Wall thickness:The thickness of the panel and side walls directly affects the resistance to deformation.

Lifting and Support:Confirm whether the lifting holes and support points on the back of the fixed disk(usually following the"Avery Point"support principle)are compatible with your installation method.Large fixed disks must be supported according to the marked points to prevent deformation due to their own weight.

Working environment and special requirements:Environment:Attention should be paid to rust prevention in humid environments(whether aging treatment has been carried out,and the quality of coating).

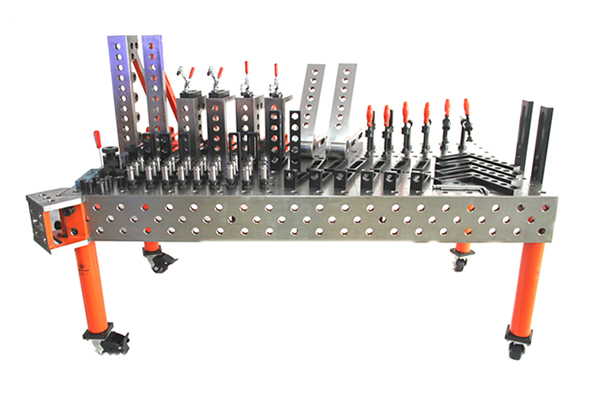

Special functions:Whether special mechanical interfaces such as T-slots,round holes,V-grooves,etc.are required.

V.Summary of decision-making process:Clarify requirements:List the maximum workpiece size,weight,work nature(inspection/assembly/welding),and accuracy requirements.

Initial selection size:workpiece size+operating margin=minimum size of the fixed plate,rounded up to the standard specification.

Load capacity calculation:Calculate the maximum load strength,consult with the supplier regarding the rated allowable load for the specified size and accuracy level of the fixture,and ensure that there is sufficient safety margin.

Comprehensive confirmation:Under the premise of meeting the requirements for size and load-bearing capacity,select the accuracy level and brand according to the budget,and confirm the structural details(rib plate,support point,surface treatment).

Final suggestion:Provide your specific working conditions(preferably with workpiece drawings or photos)to reputable cast iron steady rest manufacturers or suppliers.They can offer the most professional advice on specification selection and technical solutions.Do not make a choice solely based on price;structural rigidity and long-term accuracy stability are the key factors.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China