NewsDetails

What is the return on investment (ROI) of a 3D flexible welding platform in a small-batch, multi-variety production model?

author:admin time:2026-01-17 14:36:11 click:176

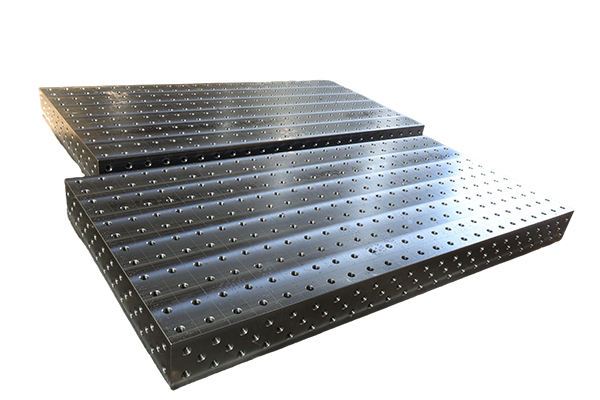

For the production model featuring small batches and multiple varieties, the return on investment (ROI) assessment of investing in a 3D flexible welding platform needs to transcend the traditional perspective of large-batch calculations. Its core value lies in enhancing comprehensive competitiveness and long-term adaptability.

1. Core investment return driver (direct benefit): Extreme reduction in tooling and fixture costs and changeover time. Traditional model: Each new product requires the design and manufacture of dedicated fixtures, which incurs high costs (tens of thousands to hundreds of thousands of yuan) and long cycles (weeks to months).

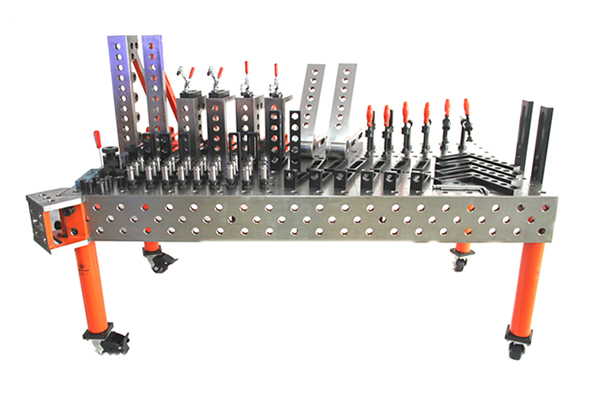

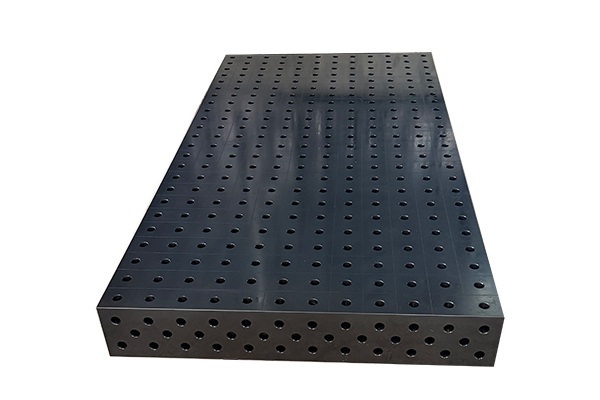

Flexible platform: Utilizing standardized and reconfigurable modular fixtures (such as hole series and grid plate fixtures), it can adapt to new workpieces through rapid adjustment and combination. The changeover time can be shortened from days to hours or even minutes, which is the most direct source of ROI in small batch mode.

Traditional model for significantly reducing programming and process preparation time: relying on manual teaching or offline programming, demanding high worker experience, and time-consuming and laborious debugging for each new part.

Flexible platform: By integrating 3D CAD models with offline programming software, it is possible to generate programs and robot paths in advance. Coupled with a weld seam tracking system, it can automatically adapt to minor deviations in workpieces, significantly reducing on-site debugging time, and achieving "programming in the morning, production in the afternoon".

Improving welding quality and consistency: Robot welding can strictly adhere to optimal parameters, avoiding the effects of human fatigue and emotions. This significantly reduces the rate of rework and scrap costs. Especially in high-value-added products with stringent welding requirements, the quality benefits are substantial.

Reducing dependence on highly skilled welders solidifies process knowledge in programs and systems, allowing ordinary operators to operate after training, alleviating production fluctuations and labor cost pressures caused by the "welding shortage".

II. Implicit strategic benefits (indirect but crucial) The ability to quickly respond to and undertake urgent and special orders, as well as economically produce "one-piece flow" or very small batch orders, has become a core competitiveness in attracting high-end customized customers, enhancing order premium capacity and customer loyalty.

A flexible system can replace multiple dedicated workstations, freeing up production space and enhancing asset efficiency. It reduces the circulation and waiting time of work-in-process products, thereby increasing output per unit area.

The accumulation of knowledge and the digital upgrade of all welding parameters and procedures into reusable digital assets lay the foundation for subsequent process optimization and digital production management, marking a crucial step in the transformation and upgrading of enterprises.

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China