NewsDetails

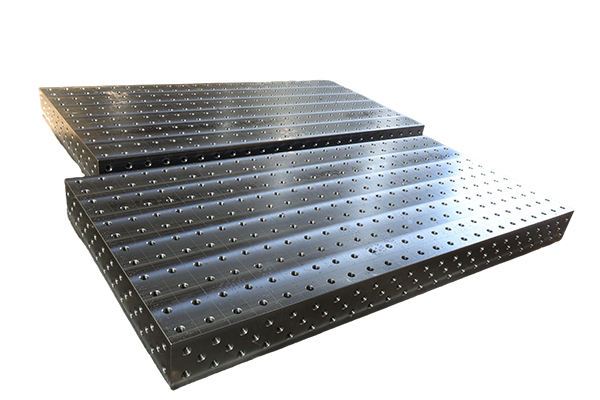

The 3D flexible welding platform has poor repeatability accuracy at the teaching points. How can it be calibrated?

author:admin time:2026-01-17 14:31:15 click:176

Step 1:Quick troubleshooting and basic calibration(to solve 80%of common problems)Check mechanical fastness and rigidity(primary step):all bolts:thoroughly inspect and tighten all mechanical connecting bolts such as those for the platform base,columns,beams,sliders,and welding gun fixtures.A single loose bolt can lead to significant deviations.

Transmission components:Manually check whether the gear and rack meshing is loose,whether the tension of the timing belt is sufficient,and whether the ball screw has axial play.

End tool:Confirm whether the welding torch(TCP)itself and its clamping mechanism are secure and free from shaking.

Calibration of"zero point"-reference point/return-to-zero accuracy:Phenomenon:After each return to zero,when moving to the same teaching point again,the position is inconsistent.

Calibration:Clean the origin switches(or magnetic grids,photoelectric sensors)and sensing blocks of each axis.

Check and adjust the relative position of the switch and the sensing block to ensure stable and accurate trigger signals.

Perform the precise"return to reference point"or"zero search"operation again.This is the benchmark for all positioning.If the benchmark is inaccurate,everything will be inaccurate.

Compensation"Gap"-Reverse Gap:Phenomenon:When moving to the same teaching point from different directions(forward/reverse),there is a fixed difference in position.

Calibration:Use a micrometer to manually test the backlash of each axis.

Locate the"Backlash Compensation"parameter in the device's numerical control system settings and enter the measured backlash value.The system will automatically apply compensation during direction changes.

Calibration of the"end point"-TCP(Tool Center Point)calibration:Phenomenon:The position of the welding torch tip is inaccurate,but the actual coordinates of the axis may be accurate.

Calibration:Re-perform TCP calibration using a precise TCP calibrator(such as a tip,three-point method,or laser calibration).This is the top priority in welding robot calibration.

Step 2:In-depth detection and advanced compensation(to address systematic errors)Measurement of repeated positioning accuracy:Use a laser interferometer or high-precision micrometer to select multiple points(especially near the teaching point)across the full range of the suspected axis.

Repeat the movement to the same point(usually 5-10 times),record the data,and calculate the repeat positioning accuracy value of that point.This can quantitatively assess the severity of the problem.

Inspect the wear of the guide rail and slider:If the repeated errors vary with position and show a trend,it may indicate poor straightness of the guide rail or wear of the slider.

A professional is required to conduct a straightness inspection using a laser interferometer.If the wear exceeds the tolerance,the worn parts need to be replaced.

Servo drive optimization:After long-term use,changes in mechanical characteristics may lead to a mismatch between the original servo parameters(gain,integration time,etc.),resulting in positioning jitter or overshoot.

Have professionals re-tune the servo system to optimize dynamic response and ensure stable and precise stopping.

Verify and update pitch error compensation:Long-term wear or load may cause a decrease in the system's positioning accuracy(absolute accuracy),affecting the repeatability of positioning.

Re-measure the positioning error of the full travel using a laser interferometer and update the screw pitch error compensation table in the numerical control system.

Step 3:Check the consistency of load with environmental and operational specifications:Ensure that the total weight and center of gravity of the workpiece and fixture remain essentially consistent during teaching and reproduction.Significant load variations can lead to minor deformations in structural components.

Thermal effect:Ensure that the equipment is fully preheated(operated for 15-30 minutes)before conducting teaching and production to eliminate the impact of thermal expansion.

Program check:Confirm whether the teaching point is in joint coordinates rather than relying on an unstable world coordinate system.Use the local workpiece coordinate system instead of the global coordinate system.

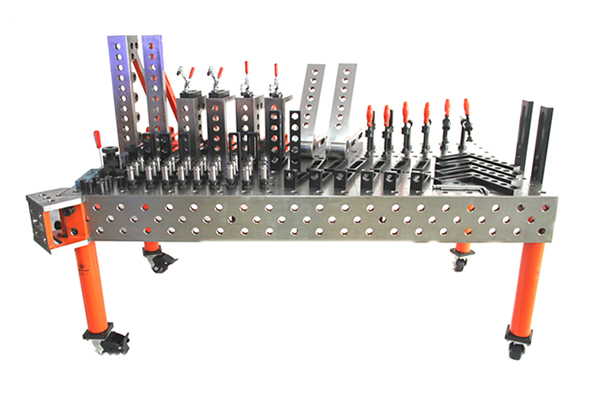

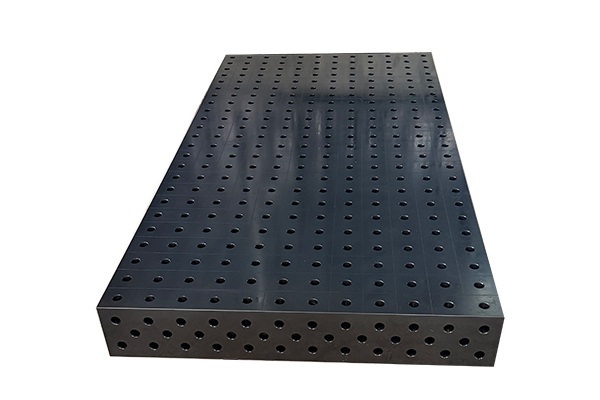

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China