NewsDetails

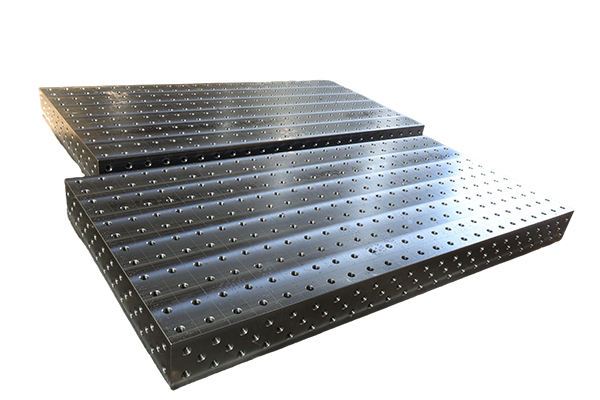

What are the routine maintenance items and cycles for the 3D flexible welding platform?

author:admin time:2026-01-17 14:30:34 click:61

What are the routine maintenance items and cycles for the 3D flexible welding platform?

1.Daily maintenance(per shift/per day)

Cleaning:Remove welding slag,dust,and oil stains from the platform,guide rails,and sliding blocks.

Lubrication inspection:Visually inspect the oil level of the automatic lubrication system,ensuring that the surfaces of the guide rails and lead screws are evenly coated with an oil film.

Operational check:After powering on,run the machine at low speed without load to listen for any abnormal noise and check whether the movement of each axis is smooth.

Key point inspection:Check the welding torch,cable,and gas hose for any damage or looseness.

II.Weekly/Monthly Maintenance

Deep cleaning and lubrication:Manually replenish and clean the guide rails,racks,and lead screws(if automatic lubrication is insufficient).

Fastening inspection:Check whether the main bolts and clamp connectors are loose.

Initial accuracy inspection:Check the repeatability of positioning accuracy at key welding positions using standard test blocks or procedures.

III.Quarterly/Semi-Annual Maintenance(Professional Level)

System maintenance:Replace the lubricating pump grease and clean the filter.

Electrical inspection:Inspect the cleanliness of the electrical cabinet,cooling fan,and the tightness of the wiring terminals.

Accuracy calibration:Use tools such as laser interferometers to detect positioning accuracy,and perform pitch compensation if necessary.

IV.Annual maintenance(comprehensive overhaul)

Comprehensive calibration:Conducted by professional engineers,it involves spatial accuracy(three-dimensional accuracy)detection and compensation.

Component inspection/replacement:Inspect the wear of the guide rail and the backlash of the screw,and replace the wearing parts if necessary.

Control system maintenance:Back up parameters and update the system(if necessary).

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China