NewsDetails

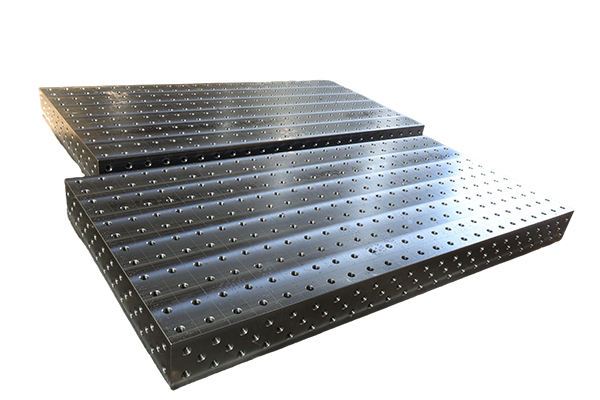

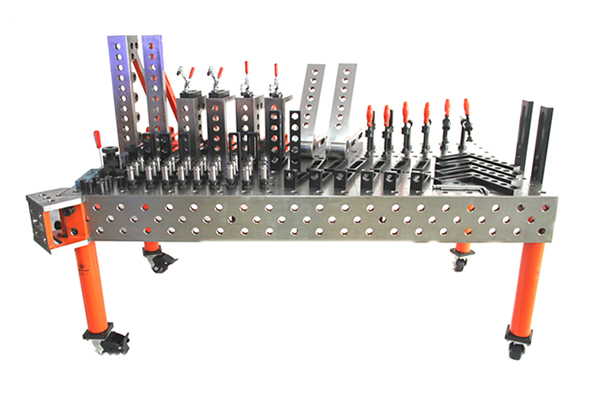

How to select the working range and number of axes for a 3D flexible welding platform based on the product family?

author:admin time:2026-01-17 14:28:58 click:115

1.Determine the scope of work(size):Consider the largest piece:Based on the size of the largest workpiece in the product family,add a safety margin of at least 300-500mm to each dimension(length,width,and height)(for fixture installation and welding torch clearance).

Observe the distribution of welds:If the welds are concentrated in a localized area,the scope can be appropriately reduced;if they are spread throughout the entire area,they must be completely covered.

2.Fixed axis count(flexibility):3 axes(X,Y,Z):Only suitable for welding workpieces in fixed positions.Ideal for products with simple weld seams that do not require adjusting the workpiece angle.

5-axis/6-axis(X,Y,Z+1-2 rotational axes):This is the most commonly used configuration.By rotating the workpiece,most welds can be positioned in the optimal flat welding position.It is suitable for product families with complex structures and multiple-angle welds.

7-axis and above(with external track or linkage with positioner):used for welding of ultra-long workpieces or those requiring extremely complex postures.Typically used in heavy machinery and large structural components.

Golden Rule:Scope:It's better to be slightly larger than necessary,rather than leaving bottlenecks for future expansion.

Number of axes:5/6 axes are preferred,as they strike an optimal balance between flexibility,cost,and efficiency,covering the welding needs of most product families.Only consider 3 axes when the weld seam is extremely simple.

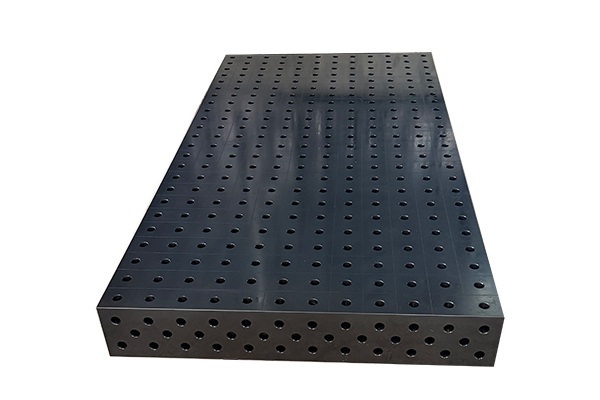

Recommended Products

Recommended Products

Contact Us

Contact Us

—— Hotline:+86 13833738896

—— Hotline:+86 17332777263

—— Email:gongliliangju@163.com

—— Whatsapp:+8615832706206

—— Address:Beihan Village, Haocun Town, Botou City, Cangzhou City, Hebei Province, China